The Significance of Spiral Wound Gaskets

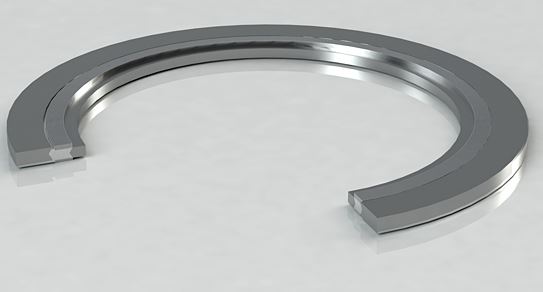

The spiral wound gasket is a type of seal which is usually placed between two different surfaces to reduce the chances of leakage. You will find various types of gaskets out there which include the metallic ones, non-metallic and semi-metallic. They are the ones used in critical applications that work under high pressure and cannot tolerate extremely high temperatures and pressures.

They are made in a way that they can balance easily if there any temperature or pressure changes during sealing, making sure everything is done safely and in the right manner. Various industries benefit from the use of the gasket. The pharmaceutical, brewing, aerospace, and engineering sectors are some that benefit a lot.

You can discover more here about this important sealing product. They are usually manufactured using a metal strip and a gasket filler that is soft. Its construction is done by bringing the metal and the filler together so that there are different occurring layers of those materials.

The filler will be the main seal to ensure everything is covered perfectly while the metal helps provide some overall strength. Some of the factors considered when choosing a material used in making the metal strips include the temperatures it can withstand, ability to resist corrosion and fluid concentration. Spiral wound gaskets can be of great significance to the different industries in the following ways.

Prevents Leakage

One great benefit of the spiral wound gasket is that it will help prevent any form of leakages in the different areas where they are used. The leakage of petrochemicals can subject people to various risks. Oil leakage can also be a major loss and pose several dangers. A spiral wound gasket is a tight sealing that will help prevent any form of leakage.

One great benefit of the spiral wound gasket is that it will help prevent any form of leakages in the different areas where they are used. The leakage of petrochemicals can subject people to various risks. Oil leakage can also be a major loss and pose several dangers. A spiral wound gasket is a tight sealing that will help prevent any form of leakage.

Withstands High Pressure

The spiral wound gasket can also withstand high pressure. It is made using various strong materials which include the outer ring, metal strips, and inner ring. They will provide a sturdy cover if subjected to high pressure. You don’t have to worry about leakages or any disappointment.…

The spiral wound gasket can also withstand high pressure. It is made using various strong materials which include the outer ring, metal strips, and inner ring. They will provide a sturdy cover if subjected to high pressure. You don’t have to worry about leakages or any disappointment.…

If you are a serious company that is focused on perfectly serving your customers, then you will definitely look for sure ways to ensure that there are no malfunctions in your company. One of the best ways that you can use to achieve this is by making use of total productive maintenance (TPM). This is a program that is dedicated to ensuring that there is effective functioning with the company. This program perfectly enforces the dissemination of information within the entire workforce. For you to run a successful company, you need to make sure that your program takes into consideration the most fundamental lessons.

If you are a serious company that is focused on perfectly serving your customers, then you will definitely look for sure ways to ensure that there are no malfunctions in your company. One of the best ways that you can use to achieve this is by making use of total productive maintenance (TPM). This is a program that is dedicated to ensuring that there is effective functioning with the company. This program perfectly enforces the dissemination of information within the entire workforce. For you to run a successful company, you need to make sure that your program takes into consideration the most fundamental lessons. When it comes to dealing with heavy machines, regular inspection is very necessary. This is because it is the one that will help to reduce chances of accidents within the company. It will also ensure that there will be a continuous operation of the company since it will do away with an unexpected breakdown of systems in the company. The TPM presentation emphasizes on this and ensures that the necessary things are perfectly done.…

When it comes to dealing with heavy machines, regular inspection is very necessary. This is because it is the one that will help to reduce chances of accidents within the company. It will also ensure that there will be a continuous operation of the company since it will do away with an unexpected breakdown of systems in the company. The TPM presentation emphasizes on this and ensures that the necessary things are perfectly done.…